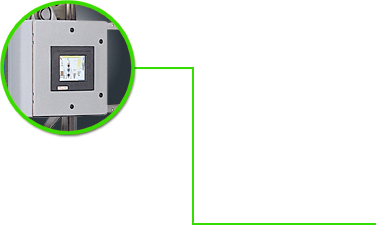

Programmable controller automatically opens a discharge valve at the end of a blending cycle, and then closes the valve to ready the mixer/

WEIGH BATCHING SYSTEMS

Move Virtually Any Bulk Material, from Any Upstream Source, to Any Downstream Destination

Whether you are sourcing material from bulk bags, silos, manual dumping stations, process equipment or all of the above; weigh batching one ingredient or 50; blending your recipe; filling containers, and/or delivering it to process vessels, packaging lines, or any other destination, Flexicon has the comprehensive selection of equipment you need for a total weigh batching solution.

From individual loss-of-weight bulk bag weigh batch dischargers to automated gain-in-weight batching/blending systems integrated with your upstream and downstream equipment, Flexicon offers you the entire range of specialized equipment—and the engineering talent—required for a smooth start-up and efficient performance.

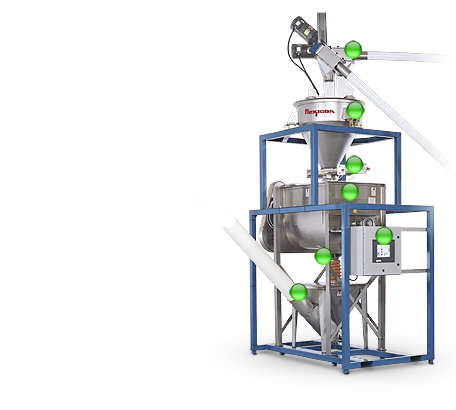

Programmable controller automatically opens the discharge valve of the Gain-In-Weight Receiving Hopper to charge the blender, and then closes the valve, allowing the hopper to weigh ingredients of another batch.

Flexible Screw Conveyors (shown), Tubular Cable Conveyors and Pneumatic Conveying Systems can transport blended material to any downstream process equipment, packaging line or storage vessel.

Programmable Controls automate the entire weigh batching and blending process, including opening/

Weigh Batching Systems can be integrated with new or existing Mixers and Blenders including Ribbon Blenders, Paddle Blenders, Plow Blenders, Vee-Cone Blenders, Fluidized Bed Mixers, Rotary Drum Mixers and others.

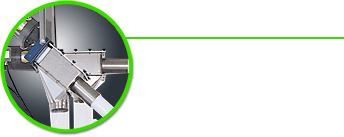

RECEIVING HOPPER

Gain-in-Weight Receiving Hopper mounted on load cells transmits weight-gain information to a programmable controller that starts and stops conveyors (or opens and closes valves) to load each ingredient in sequence. Simultaneous blending of the batch and weighing of a subsequent batch decreases cycle times.

SCREW CONVEYORS

Flexicon Flexible Screw Conveyors (shown), Tubular Cable Conveyors and Pneumatic Conveying Systems can source batch ingredients from any nearby or distant plant location.

Equally as crucial to your weigh batching success is the proven ability of Flexicon equipment to move your material — at high rates for fast batching cycles and at steady dribble-feed rates for highly accurate weighments—and to deliver recipes with no separation of blended materials and no exposure to potential contamination.

Whether your ingredients are free-flowing pellets, powders that pack, bridge or smear, products that fluidize, or blends prone to separation, Flexicon can move them positively, weigh them accurately, and deliver them in prime condition.

This turnkey, gain-in-weight batching system conveys material from four Flexicon bulk bag dischargers to a weigh hopper which discharges into a blender. During the blending operation, a subsequent batch is being weighed by the hopper, thereby reducing cycle times. In this case, blended batches are discharged directly into shipping containers.

This Automated Weigh Batching System conveys material from Flexicon bulk bag dischargers via Flexicon flexible screw conveyors to a weigh hopper mounted on load cells at mezzanine level. Weigh batches are automatically discharged through a rotary air lock into a Flexicon pneumatic conveying system transporting the pre-weighed batch to a blender.

The weigh batch filling head of this bulk bag gain-in-weight batching system can be cantilever-mounted (shown), or mounted remotely above any discharge point desired; the flexible screw conveyor can transport material at any angle to any nearby or distant plant location. Electric hoist and trolley model shown.

Flexicon Loss-of-Weight Batching Systems discharge one or more bulk bags while weighing the material and conveying the batch directly to a common hopper, blender, conveyor, shipping container, or process vessel automatically, accurately, and economically. This loss-of-weight system is mounted on load cells which transmit the amount of weight lost to a controller which, in turn, stops the conveyor once the target batch weight has been reached.